Automation solutions

Automation solutions

Automation solutions

Automation

Industry 4.0

Automation

Industry 4.0

What is industry 4.0? This term describes the industrial revolution that is just taking place in the world. Use the potential of automation, data collection and processing as well as human- machine integration for the optimal management of your factory.

Thanks to our support, you can become a leader in your industry.

We are able to help in every aspect. From sensors, through PLC controllers, to Business Intelligence systems. Join the fourth industrial revolution and gain advantage!

automatyzacja

Industry 4.0

What is industry 4.0? This term describes the industrial revolution that is just taking place in the world. Use the potential of automation, data collection and processing as well as human- machine integration for the optimal management of your factory.

Thanks to our support, you can become a leader in your industry.

We are able to help in every aspect. From sensors, through PLC controllers, to Business Intelligence systems. Join the fourth industrial revolution and gain advantage!

AUTOMATION

NEAT

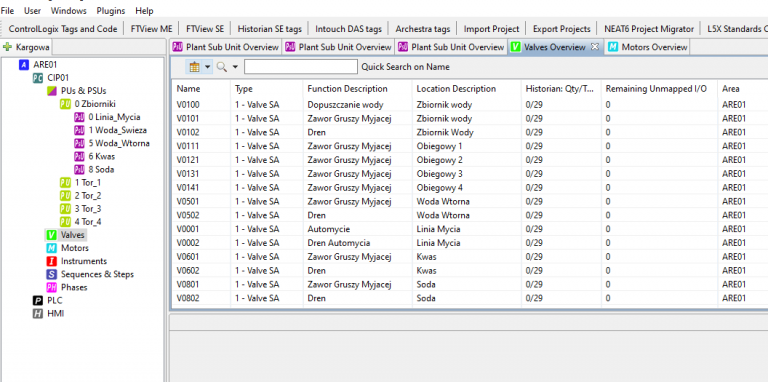

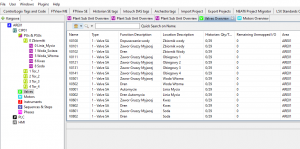

Nestle Engineering Automation Toolbox or NEAT in short is a concept developed for Nestle by Rockwell Automation. It is a set of design and programming assumptions and a special development tool that helps to unify the program structure and logically divide the plant. It is a very convenient solution for the maintenance department, but it is often a challenge for integrators as it requires getting to know the new system and changing your own habits.

Magma's Automation Department already has extensive experience with NEAT and many completed investments on this platform. Our programmers are up to date with new products and they move more and more freely in NEAT software.

Whether you are an end customer or an integrator who needs support with an investment for Nestle, our automation engineers are here to help.

Automation

NEAT

Nestle Engineering Automation Toolbox or NEAT in short is a concept developed for Nestle by Rockwell Automation. It is a set of design and programming assumptions and a special development tool that helps to unify the program structure and logically divide the plant. It is a very convenient solution for the maintenance department, but it is often a challenge for integrators as it requires getting to know the new system and changing your own habits.

Magma's Automation Department already has extensive experience with NEAT and many completed investments on this platform. Our programmers are up to date with new products and they move more and more freely in NEAT software.

Whether you are an end customer or an integrator who needs support with an investment for Nestle, our automation engineers are here to help.

automatyzacja

NEAT

Nestle Engineering Automation Toolbox or NEAT in short is a concept developed for Nestle by Rockwell Automation. It is a set of design and programming assumptions and a special development tool that helps to unify the program structure and logically divide the plant. It is a very convenient solution for the maintenance department, but it is often a challenge for integrators as it requires getting to know the new system and changing your own habits.

Magma's Automation Department already has extensive experience with NEAT and many completed investments on this platform. Our programmers are up to date with new products and they move more and more freely in NEAT software.

Whether you are an end customer or an integrator who needs support with an investment for Nestle, our automation engineers are here to help.

Automation

Device calibration

Automation

Device calibration

One of the most important things in production is stable, reliable and accurate measurement of process parameters. To ensure it, you need not only high-class equipment, but also proper calibration and operation of measuring devices.

Our specialists are able to perform such calibration during machine start-up and during its operation.

Correct maintenance of your measuring devices will ensure reliable operation for many years and help to avoid unexpected downtime.

automatyzacja

device calibration

One of the most important things in production is stable, reliable and accurate measurement of process parameters. To ensure it, you need not only high-class equipment, but also the correct calibration and operation of measuring devices. Our specialists are able to perform such calibration during machine start-up and during its operation. Correct maintenance of your measuring devices will ensure reliable operation for many years and help to avoid unexpected downtime.

Automation

Retrofitting - Give your machine a new lease of life

Machines prepared for operation in industrial conditions may operate for several dozen years. Unfortunately, there is often a need to modernize the control system or the system simply breaks down, and there are no substitutes on the market.

Together with us, you can upgrade your machine to a modern control system, increasing its efficiency and unlocking new potential without having to buy a new one.

Automation

retrofitting - Give your machine a new life

Machines prepared for operation in industrial conditions may operate for several dozen years. Unfortunately, there is often a need to modernize the control system or the system simply breaks down, and there are no substitutes on the market.

Together with us, you can upgrade your machine to a modern control system, increasing its efficiency and unlocking new potential without having to buy a new one.

automatyzacja

Retrofitting - Give your machine a new lease of life

Machines prepared for operation in industrial conditions may operate for several dozen years. Unfortunately, there is often a need to modernize the control system or the system simply breaks down, and there are no substitutes on the market.

Together with us, you can upgrade your machine to a modern control system, increasing its efficiency and unlocking new potential without having to buy a new one.

Automation

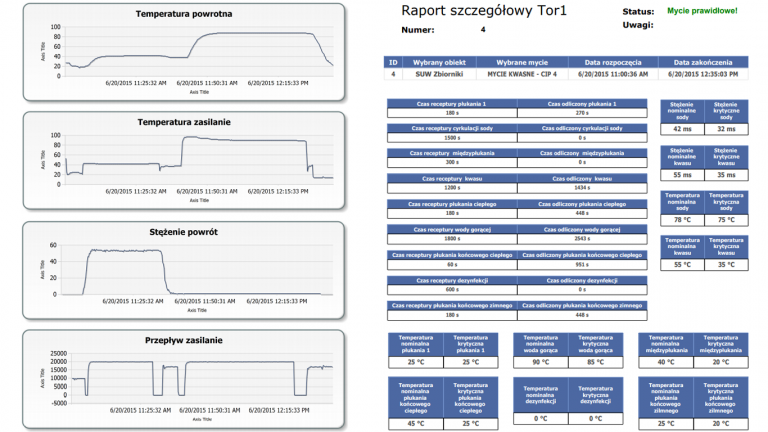

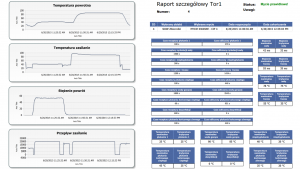

Reporting systems

Regardless of the diligence of our employees or the number of checks carried out, the factor that ultimately verifies the correct performance of the process is an automatically generated report. It does not matter whether the production, washing process, batch storage, number of failures, the report is a document confirming faultlessness.

Keep your factory safe with Magma Report!

Automation

Reporting systems

Regardless of the diligence of our employees or the number of checks carried out, the factor that ultimately verifies the correct performance of the process is an automatically generated report. It does not matter whether the production, washing process, batch storage, number of failures, the report is a document confirming faultlessness.

Magma Report is a reporting system tailored to your needs. Automatically generated on the basis of information from production machines, requiring no human intervention. It is unequivocal evidence in cases requiring verification of past processes. It confirms the belief that the information contained therein is reliable.

Keep your factory safe with Magma Report!

automation

reporting systems

Regardless of the diligence of our employees or the number of checks carried out, the factor that ultimately verifies the correct performance of the process is an automatically generated report. It does not matter whether the production, washing process, batch storage, number of failures, the report is a document confirming faultlessness.

Magma Report is a reporting system tailored to your needs. Magma Report is a reporting system tailored to your needs. Automatically generated on the basis of information from production machines, requiring no human intervention. It is unequivocal evidence in cases requiring verification of past processes. It confirms the belief that the information contained therein is reliable.

Keep your factory safe with Magma Report!

Automation

Magma Service

No time or tools to perform periodical surveys? Would you like properly manage unexpected downtime? Do you need minor improvements or repairs? Leave it to us!

Regardless of whether you have Magma products or machines from other manufacturers, you can always count on our service support despite the expiry of the warranty. We are able to quickly restore the production line to work, we help in diagnostics.

Automation

Magma Service

No time or tools to conduct przeglądy okresowe? Would you like properly manage unexpected downtime? Do you need minor improvements or repairs? Leave it to us!

Regardless of whether you have Magma products or machines from other manufacturers, you can always count on our service support despite the expiry of the warranty. We are able to quickly restore the production line to work, we help in diagnostics.

Annual software subscriptions, specialized tools, employee training, time, responsibility - all this can generate huge maintenance costs. Contact us and see how beneficial a service contract with Magma can be.

automatyzacja

Magma Service

No time or tools to perform periodical surveys? Would you like properly manage unexpected downtime? Do you need minor improvements or repairs? Leave it to us!

Regardless of whether you have Magma products or machines from other manufacturers, you can always count on our service support despite the expiry of the warranty. We are able to quickly restore the production line to work, we help in diagnostics.

Annual software subscriptions, specialized tools, employee training, time, responsibility - all this can generate huge maintenance costs. Contact us and see how beneficial a service contract with Magma can be.